| Item # | Description | Barcode |

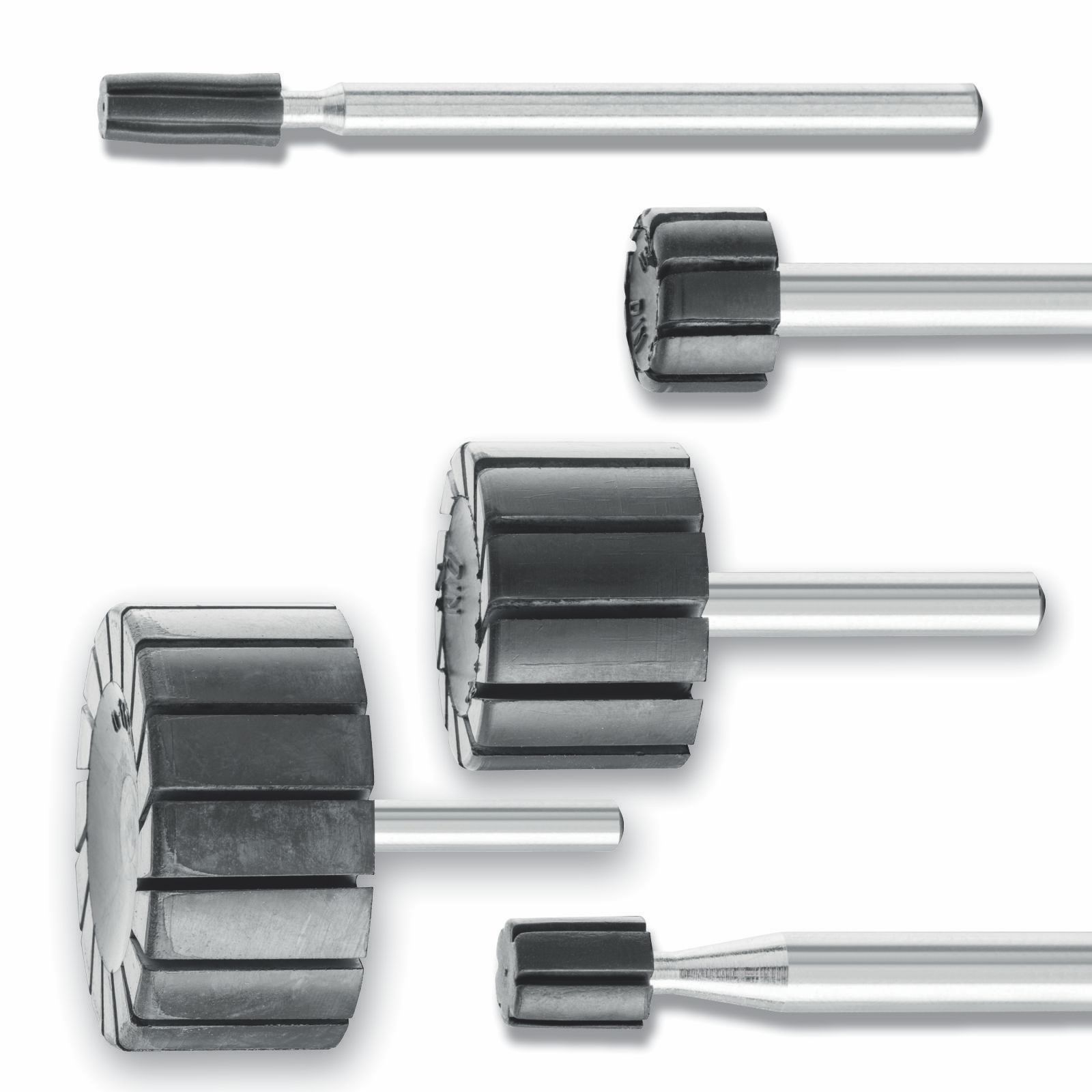

| 42100410 | RUBBER DRUM HOLDERS GK 04 x 10mm/6mm Shaft | 4007220146712 |

| 42100413 | RUBBER DRUM HOLDERS GK 04 x 10mm/3mm Shaft | 4007220146729 |

| 42100610 | RUBBER DRUM HOLDERS GK 06 x 10mm/6mm Shaft | 4007220146736 |

| 42100613 | RUBBER DRUM HOLDERS GK 06 x 10mm/3mm Shaft | 4007220146743 |

| 42100810 | RUBBER DRUM HOLDERS GK 08 x 10mm/6mm Shaft | 4007220146750 |

| 42100813 | RUBBER DRUM HOLDERS GK 08 x 10mm/3mm Shaft | 4007220146767 |

| 42101000 | RUBBER DRUM HOLDERS GK 10 x 10mm/6mm Shaft | 4007220146774 |

| 42102000 | RUBBER DRUM HOLDERS GK 10 x 20mm/6mm Shaft | 4007220146781 |

| 42103000 | RUBBER DRUM HOLDERS GK 13 x 10mm/6mm Shaft | 4007220146798 |

| 42104000 | RUBBER DRUM HOLDERS GK 13 x 25mm/6mm Shaft | 4007220146804 |

| 42105000 | RUBBER DRUM HOLDERS GK 15 x 10mm/6mm Shaft | 4007220146811 |

| 42106000 | RUBBER DRUM HOLDERS GK 15 x 30mm/6mm Shaft | 4007220146828 |

| 42106500 | RUBBER DRUM HOLDERS GK 19 x 25mm/6mm Shaft | 4007220146835 |

| 42107000 | RUBBER DRUM HOLDERS GK 22 x 20mm/6mm Shaft | 4007220146842 |

| 42107500 | RUBBER DRUM HOLDERS GK 25 x 25mm/6mm Shaft | 4007220146866 |

| 42108000 | RUBBER DRUM HOLDERS GK 30 x 20mm/6mm Shaft | 4007220146873 |

| 42109000 | RUBBER DRUM HOLDERS GK 30 x 30mm/6mm Shaft | 4007220146880 |

| 42109500 | RUBBER DRUM HOLDERS GK 38 x 25mm/6mm Shaft | 4007220146903 |

| 42110000 | RUBBER DRUM HOLDERS GK 45 x 30mm/6mm Shaft | 4007220146927 |

| 42110500 | RUBBER DRUM HOLDERS GK 51 x 25mm/6mm Shaft | 4007220146941 |

| 42111006 | RUBBER DRUM HOLDERS GK 60 x 30mm/6mm Shaft | 4007220146958 |

| 42112000 | RUBBER DRUM HOLDERS GK 75 x 30mm/8mm Shaft | 4007220146972 |

| 42113000 | RUBBER DRUM HOLDERS GK 100 x 40mm/8mm Shaft | 4007220146989 |

Menu