| Item # | Description | Grit | MOQ | Barcode |

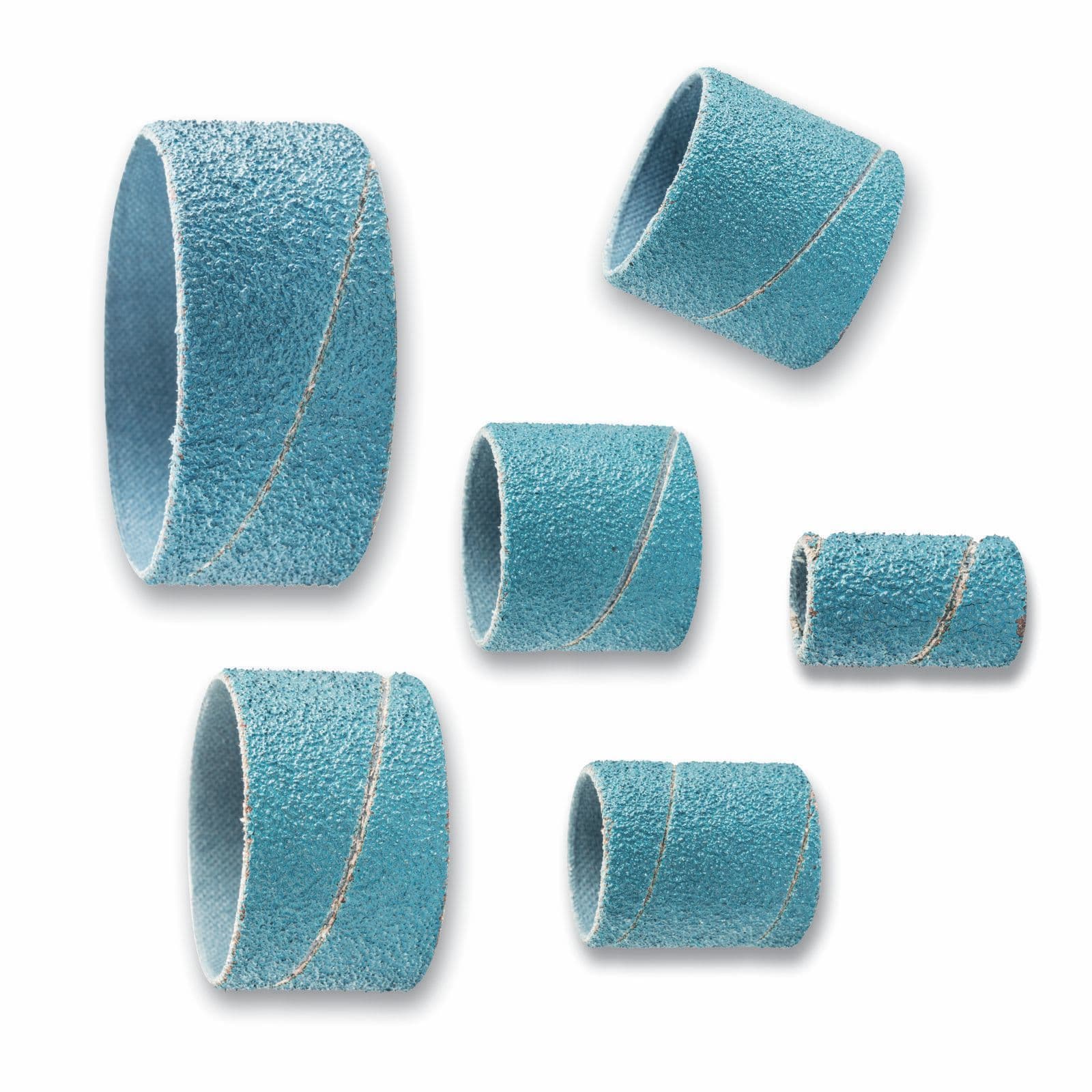

| 42217064 | ABR.SPIRAL BANDS GSB 1325 Z | 60 | 100 | 4007220804872 |

| 42217065 | ABR.SPIRAL BANDS GSB 1325 Z | 80 | 100 | 4007220804889 |

| 42217092 | ABRAS. SPIRAL BANDS GSB 1925 Z | 40 | 100 | 4007220804896 |

| 42217094 | ABRAS. SPIRAL BANDS GSB 1925 Z | 60 | 100 | 4007220804940 |

| 42217095 | ABRAS. SPIRAL BANDS GSB 1925 Z | 80 | 100 | 4007220804957 |

| 42217112 | ABRAS. SPIRAL BANDS GSB2525 Z | 40 | 100 | 4007220805022 |

| 42217114 | ABRAS. SPIRAL BANDS GSB2525 Z | 60 | 100 | 4007220805084 |

| 42217115 | ABRAS. SPIRAL BANDS GSB2525 Z | 80 | 100 | 4007220805091 |

| 42217132 | ABRAS. SPIRAL BANDS GSB 3030 Z | 40 | 100 | 4007220805145 |

| 42217133 | ABRAS. SPIRAL BANDS GSB 3030 Z | 50 | 100 | 4007220805152 |

| 42217134 | ABRAS. SPIRAL BANDS GSB 3030 Z | 60 | 100 | 4007220805176 |

| 42217135 | ABRAS. SPIRAL BANDS GSB 3030 Z 80 BULK-P | 80 | 100 | 4007220805183 |

| 42217142 | ABRAS. SPIRAL BANDS GSB3825 Z 40 BULK-P. | 40 | 100 | 4007220805190 |

| 42217144 | ABRAS. SPIRAL BANDS GSB3825 Z 60 BULK-P. | 60 | 100 | 4007220805206 |

| 42217152 | ABRAS. SPIRAL BANDS GSB4530 Z40 BULK-P. | 40 | 100 | 4007220805664 |

| 42217154 | ABRAS. SPIRAL BANDS GSB4530 Z60 BULK-P. | 60 | 100 | 4007220805725 |

| 42217155 | ABRAS. SPIRAL BANDS GSB4530 Z80 BULK-P. | 80 | 100 | 4007220805732 |

| 42217162 | ABRAS. SPIRAL BANDS GSB5125 Z40 BULK-P. | 40 | 100 | 4007220803943 |

| 42217164 | ABRAS. SPIRAL BANDS GSB5125 Z60 BULK-P. | 60 | 100 | 4007220803950 |

| 42217165 | ABRAS. SPIRAL BANDS GSB5125 Z80 BULK-P. | 80 | 100 | 4007220803967 |

Menu