| Item # | Description | Grit | MOQ | Barcode |

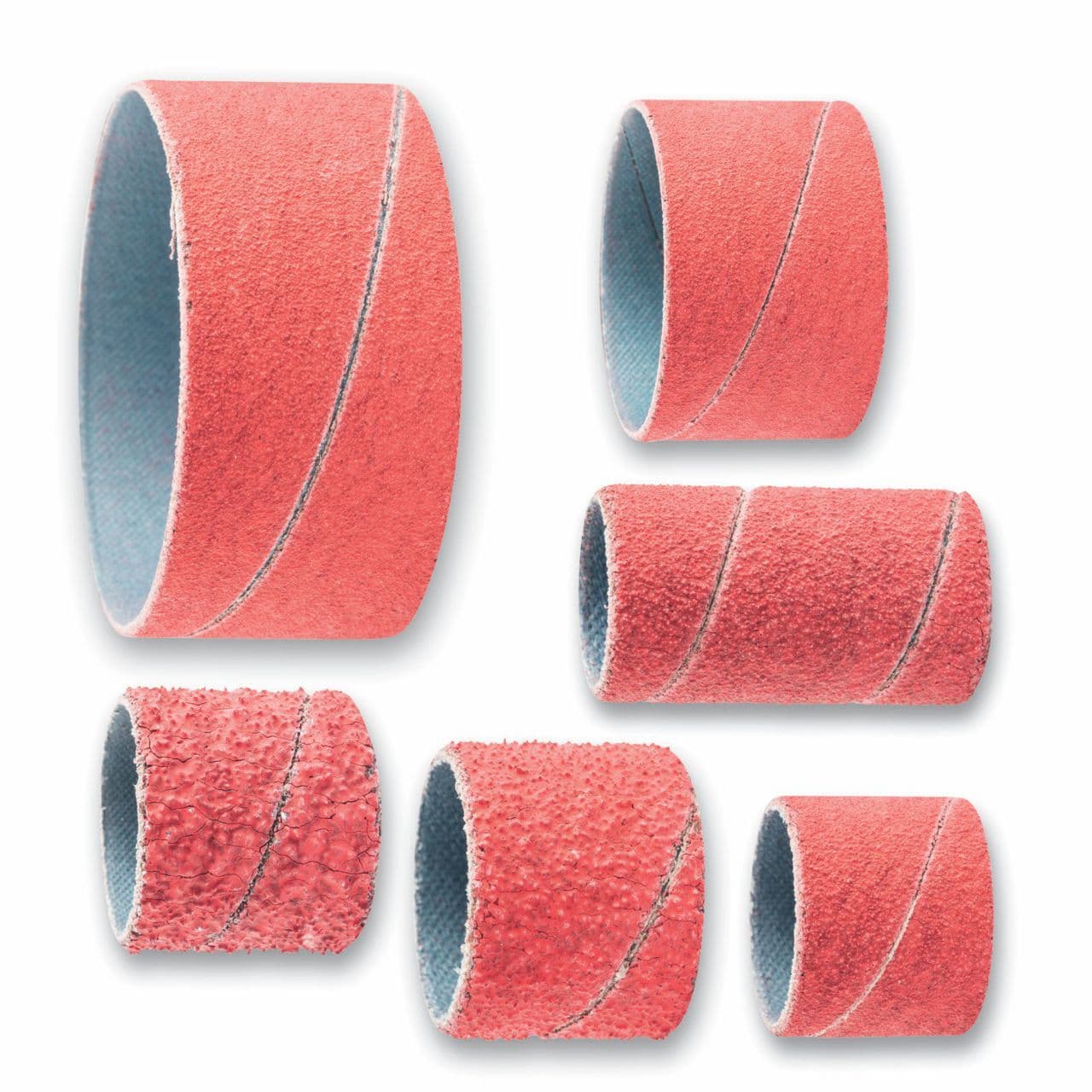

| 42204205 | ABRAS. SPIRAL BANDS GSB 1325 CO-COOL 60 | 60 | 100 | 4007220088074 |

| 47501467 | SA-BAND GSB 1020 CO-COOL 60 S0145 | 60 | 100 | 4007220809075 |

| 47501492 | SA-BAND GSB 1020 CO-COOL | 80 | 100 | 4007220868973 |

| 42206305 | ABRAS. SPIRAL BANDS GSB1530 CO-COOL 60 | 60 | 100 | 4007220772195 |

| 42206308 | ABRAS. SPIRAL BANDS GSB1530 CO-COOL 80 | 80 | 100 | 4007220772201 |

| 42206312 | ABRAS. SPIRAL BANDS GSB1530 CO-COOL 120 | 120 | 100 | 4007220772218 |

| 42207305 | ABRAS. SPIRAL BANDS GSB2220 CO-COOL 60 | 60 | 100 | 4007220772225 |

| 42207308 | ABRAS. SPIRAL BANDS GSB2220 CO-COOL 80 | 80 | 100 | 4007220772232 |

| 42207312 | ABRAS. SPIRAL BANDS GSB2220 CO-COOL 120 | 120 | 100 | 4007220772249 |

| 47502567 | SA-ABR.SPIRAL BANDS GSB 2525 CO-COOL 36 | 36 | 100 | 4007220974971 |

| 42207705 | ABRAS. SPIRAL BANDS GSB2525 CO-COOL 60 | 60 | 100 | 4007220772256 |

| 42207708 | ABRAS. SPIRAL BANDS GSB2525 CO-COOL 80 | 80 | 100 | 4007220772263 |

| 42207712 | ABRAS. SPIRAL BANDS GSB2525 CO-COOL 120 | 120 | 100 | 4007220772270 |

| 42209302 | ABRAS. SPIRAL BANDS GSB3030 CO-COOL 36 | 36 | 100 | 4007220772287 |

| 42209305 | ABRAS. SPIRAL BANDS GSB3030 CO-COOL 60 | 60 | 100 | 4007220772294 |

| 42209308 | ABRAS. SPIRAL BANDS GSB3030 CO-COOL 80 | 80 | 100 | 4007220772317 |

| 42209312 | ABRAS. SPIRAL BANDS GSB3030 CO-COOL 120 | 120 | 100 | 4007220772331 |

| 42210302 | ABRAS. SPIRAL BANDS GSB4530 CO-COOL 36 | 36 | 100 | 4007220772355 |

| 42210305 | ABRAS. SPIRAL BANDS GSB4530 CO-COOL 60 | 60 | 100 | 4007220772362 |

| 42210308 | ABRAS. SPIRAL BANDS GSB4530 CO-COOL 80 | 80 | 100 | 4007220772393 |

| 42211302 | ABRAS. SPIRAL BANDS GSB6030 CO-COOL 36 B | 36 B | 100 | 4007220772416 |

| 42211305 | ABRAS. SPIRAL BANDS GSB6030 CO-COOL 60 B | 60 B | 100 | 4007220772423 |

| 42211308 | ABRAS. SPIRAL BANDS GSB6030 CO-COOL 80 B | 80 B | 100 | 4007220772430 |

| 42211312 | ABRAS. SPIRAL BANDS GSB6030 CO-COOL 120 | 120 | 100 | 4007220772447 |

Menu